-

Pre-Made Packaging Pouches

If you need it, Huaqiang can provide you with ready-made packaging bags, including center-sealed bags and three-side-sealed bags, so that you can directly use them with the filling machine to improve the efficiency of the product packaging process.

Send Email Details

In order to meet the packaging needs of customers for different products, we have configured 5 automatic bag making machines. The bag making machine has stable performance and convenient adjustment, and can produce at high speed to meet the requirements of batch supply. We also have two highly efficient gravure printing machines that can complete up to nine-color printing, so that the surface of the packaging bag has a clear and exquisite printing effect, which increases the commodity value of your product.

The materials of these packaging bags are generally made of multiple layers. According to your different needs, we provide a variety of materials and structures for you to choose from. -

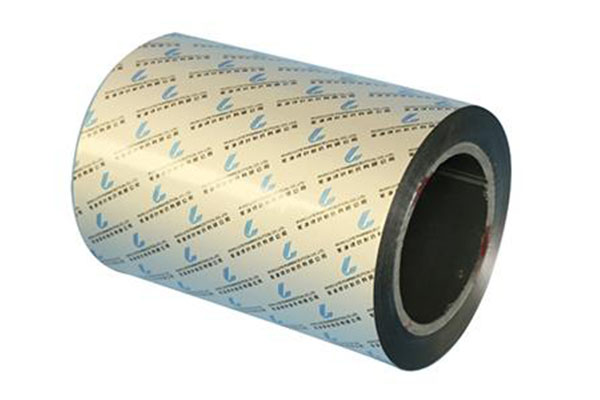

Polyester/Aluminum/Polypropylene Composite Film PET - AL - CPP

Polyester/aluminum/polypropylene composite film has very strong sealing and barrier properties. Oxygen, moisture and ultraviolet rays will not affect the packaged objects, and no bacteria will grow in the package. This high-barrier metallized film can be directly used as room temperature packaging for liquids, or as packaging for medical products such as infusion bags.

Send Email Details -

Polypropylene/Polyethylene Composite Film BOPP - LDPE

Polypropylene/polyethylene composite film is a plastic composite film with a relatively simple structure but wide applicability. It can be used to package various granular and powder products, including snacks, medicines, dietary supplements, etc. For products with fast market circulation and short storage time requirements, this is a very cost-effective packaging material.

Send Email Details -

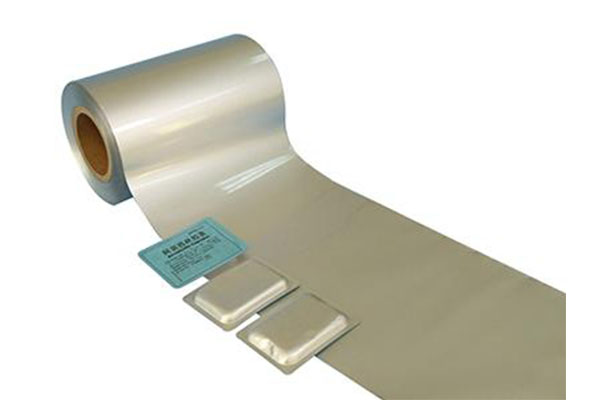

Modified Atmosphere Packaging Film

We provide high-barrier composite films of different structures in rolls, which can be used as modified atmosphere packaging films. This high-barrier film can effectively reduce the permeability of moisture and oxygen, thereby helping you perfectly control the gas composition in each package, providing the best storage conditions for your products, reducing product oxidation and corruption, and extending the shelf life of products. For example, nitrogen flushing is often chosen in food and beverage packaging to reduce the oxygen content in the package, thereby delaying corruption. The packaging of medicines and dietary supplements often requires the use of modified atmosphere packaging films to strictly control the moisture and oxygen content, allowing consumers to store them in the medicine cabinet for a longer time. In addition, modified atmosphere packaging films are also often used in the packaging of snacks, coffee beans, fresh fruits and vegetables.

Send Email Details -

Polyamide Film/Aluminum/PVC Hard Double Aluminum

Cold stamped aluminum is one of the composite materials with the best barrier properties. It adopts a composite structure of PA/AL/PVC. The aluminum foil in the middle can 100% isolate water vapor, oxygen, and ultraviolet rays. Therefore, it is specially used to make blister packaging for medicines. Cold-formed aluminum can reliably maintain the stability of drug efficacy and effectively extend the shelf life.

Send Email Details -

Polypropylene/Aluminum/Polyethylene Composite Film BOPP - AL- LDPE

Polypropylene/aluminum/polyethylene composite film has excellent barrier properties, strength and sealing. On the one hand, it can protect products from being corroded by light, moisture and oxygen, greatly extending the shelf life of goods; on the other hand, its stable nature also prevents it from being corroded by the product itself, and even products with certain corrosiveness can be packaged. It is mainly used for pharmaceutical packaging.

Send Email Details