-

Polyester/Aluminum/Polyethylene Composite Film PET - AL - LDPE

Polyester/aluminum/polyethylene composite film is made by dry lamination process, and its surface printing effect is excellent, which can help you increase the value of your products. It also has very reliable barrier properties, so neither gas, water vapor nor UV rays can affect your products. This composite film is very suitable for packaging pharmaceuticals, including tablets, granules, powders, etc.

Send Email Details -

Pillow Packaging Film

We supply composite packaging films of various structures in rolls, which can adapt to automated packaging equipment, including pillow packaging machines, filling machines, etc., to package various granules, powders and other products. Compared with pre-made bags, direct use of roll film packaging can improve productivity and reduce the average manufacturing cost of each bag of products. This packaging roll film is especially suitable for you when you need longer operation and higher output.

Send Email Details

According to customer requirements, we can provide unprinted film or printed film, and can achieve up to nine colors of printing. Whether you need an economical and practical plastic composite film or an aluminum foil composite film with better barrier properties, we can provide it. We will help you choose the most suitable material composition and structure according to the characteristics of the product you want to package. -

Polyester/Vacuum Aluminized Cast Polypropylene/Polyethylene Composite Film PET - VMPET - PE

Polyester/aluminized polyester/polyethylene composite film is widely used in medicine and food packaging. The middle layer of this composite film is aluminized polyester, that is, a layer of aluminum is plated on the surface of the polyester film by vacuum aluminizing, which can effectively play the role of light protection and barrier. The surface layer is also a polyester film with good barrier performance, which not only further improves the sealing performance, but also enables the film surface to carry printing ink well, and the printing effect is rich in color and clear in pattern. The inner layer of polyethylene material makes the heat sealing process easier during bag making, and the pouch made has excellent heat sealing strength, further extending the shelf life of the packaged goods.

Send Email Details -

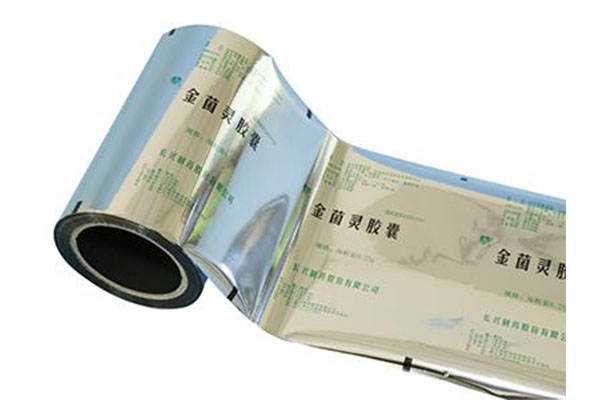

Aluminum Foil For Blister Packaging

Aluminum foil has super strong barrier properties, and can provide almost absolute barrier protection against oxygen, moisture and light. In terms of barrier properties, the advantages of aluminum foil are unmatched. No matter what kind of metal-plated film or film coated with special materials, it cannot completely replace the advantages of aluminum foil.

Send Email Details

This kind of aluminum foil can be heat-sealed, printable, and easy to puncture. It can be heat-sealed with plastic hard sheets such as PVC and PVDC to make aluminum-plastic blister packaging. It is mainly used to package pharmaceutical tablets, capsules, pills and other products. In addition, it can also be used for blister packaging of food, health products, candy and other products. -

Polypropylene/Vacuum Aluminized Cast Polypropylene Composite Film BOPP - VMCPP

Polypropylene/vacuum aluminum cast polypropylene composite film has beautiful appearance, good glossiness, and certain sealing performance. Because there is a layer of aluminum in the middle, this composite film can effectively block gas and moisture. It provides satisfactory aesthetics and barrier properties at an affordable price, which can help your products extend the shelf life. In addition to common pharmaceutical granules and powders, polypropylene/vacuum aluminum cast polypropylene composite film is also very suitable for packaging products such as biscuits, puffed foods, and cosmetics.

Send Email Details -

Stick Packaging Composite Film

Stick packaging is very suitable for packaging various powder products, such as dietary supplements, beverage powders, milk powder, instant coffee, etc. The stick design makes it very portable and easy to open and pour out the contents. It is worth noting that stick packaging can save 40% of packaging materials compared to ordinary pouch packaging, which can directly help you reduce product costs.

Send Email Details

We are particularly good at making stick packaging composite films with barrier layers, which have stronger chemical resistance and make your products completely unaffected by oxygen, light and moisture in the air, and get more comprehensive protection. We can also help you print on the composite film. We have a high-speed gravure printing machine that can achieve nine-color printing, which is enough to complete various bright patterns or text printing to add value to your products.

We use different materials to make composite films with different structures, and have the ability to customize and develop the most suitable packaging composite materials for you according to your specific needs. If you are looking for reliable composite materials for stick packaging, please contact us for more targeted professional advice.